Eagle Connecting Rods Torque Specs

Outer main cap bolt.

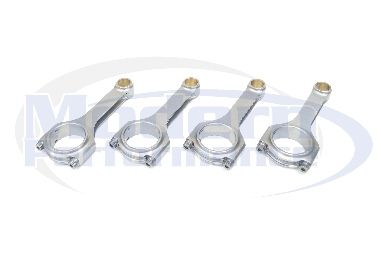

Eagle connecting rods torque specs. Eagle rods are offered with a variety of different bolts. Eagle has arp custom make bolts to our specifications. Inner main cap bolt. Eagle h beam connecting rods are manufactured from a two piece forging.

It is equally important to torque properly to provide proper strength to insure the big end of the rod sizing is correct. Tap into place before installing bolts do not. Lbs bolt stretch bolt 7 16 arp 8740 7 1 6 arp 2000 7 16 arp l 19. Ad performance scat rod bolt torque specifications rod torque specsimportant installation instructions1 disassemble rods and thoroughly clean including bolt and beam threads to remove rust preventative.

The calculation of those values is solely up to the rod manufacturer. To insure optimum service please read the following. Aftermarket connecting rod manufacturers. The rod cap is forged separately so that the grain runs perpendicular to the load forces which strengthens the rod.

Proper bolt torque is paramount to rod strength and life. 3 install rods by bringing cap and beam into alignment. Eagle does not use off the shelf arp bolts. Each of which has a different torque requirement.

2 apply arp molylube to the threads and under the head of each bolt. Proper bolt torque is paramount to rod strength and life. Thank you for selecting eagle specialty products connecting rods. Although it is a more expensive process all eagle esp 3 d connecting rods also include higher content of nickel chrome which increases the strength fatigue life without making the connecting.

Earp machine 1 928 428 3835. 4340 specs allow a range of different materials to achieve the desired results. Many aftermarket connecting rods are manufactured from 4340 steel. We stnve to maintain the highest quality products and services.

Eagle rods are offered with a variety of different bolts. Beware of connecting rods that do not include torque specifications. Eagle does not use off the shelf arp bolts. The forging process forces the grain into the shape of a connecting rod resulting in a superior fatigue life.

Improper torque will result in premature rod failure. Eagle has now begone switching from 5 16 rod bolts to 3 8 rod bolts for extra strength and durability. The big end bore of the connecting rod is a stressed bore in much the same way as cylinders are on a block. Do not use torque specs for off the shelf arp bolts.

If you have aftermarket connecting rods with an arp bolt please use the chart below to contact the rod manufacturer for the stretch torque value. Each of which has a different torque requirement. Do not use torque specs for off the shelf arp bolts.

.jpg?x-oss-process=image/auto-orient,1/quality,q_70/format,webp)

.jpg?x-oss-process=image/auto-orient,1/quality,q_70/format,webp)

.jpg?x-oss-process=image/auto-orient,1/quality,q_70/format,webp)

.jpg?x-oss-process=image/auto-orient,1/quality,q_70/format,webp)

.jpg?x-oss-process=image/auto-orient,1/quality,q_70/format,webp)