E6011 Welding Rod Amperage

Claims for warranty must be made within 90 days of the date of purchase.

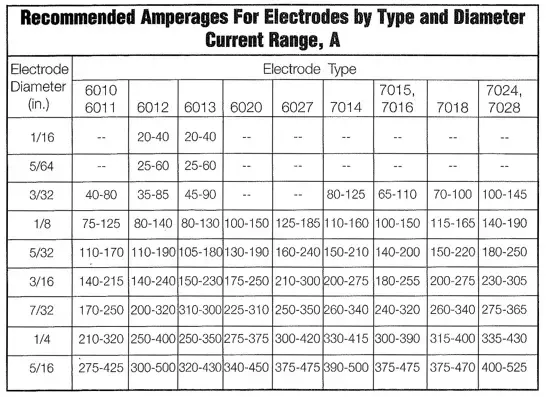

E6011 welding rod amperage. Since welding rods are powered by electric currents through the welding machine setting the right current or amperage is critical to the process to ensure a successful weld and a strong metal joint. E6011 welding rod applications amperage settings tips last updated. In turn the rod diameter you use depends on the thickness of the steel you are welding. Thanks for submitting your welding question exit e6011 welding rods see more stick welding tips.

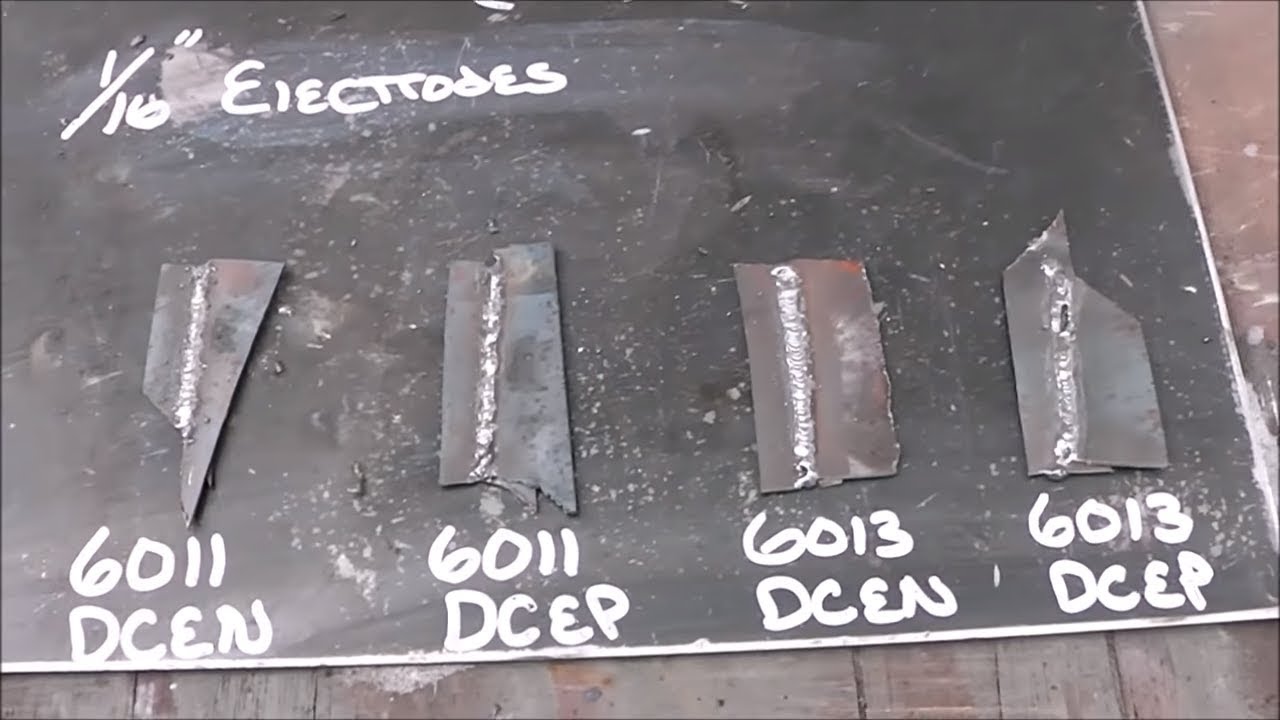

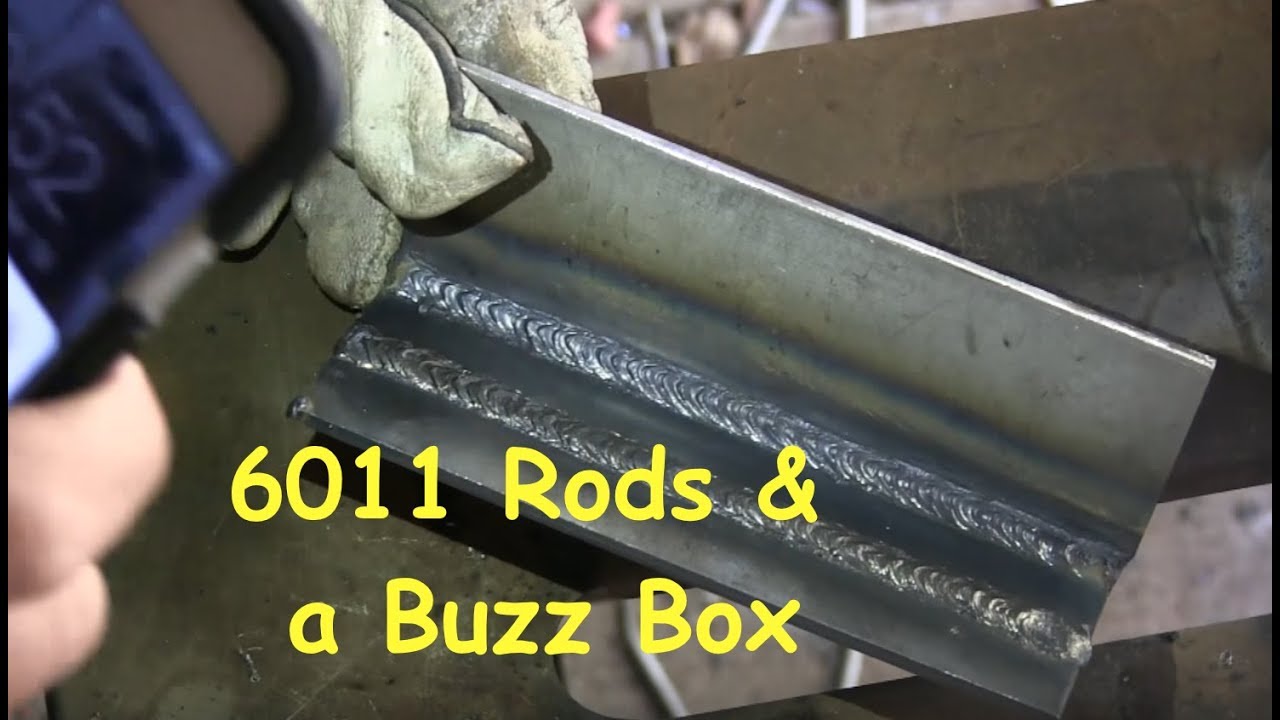

Being a fast freeze welding rod the e6011 electrode can be used in all welding positions. A rule of thumb is to use 30 amps of current per 1 32 inch of rod diameter. Tensile strength 60 000 psi amperage 80 130 amps ac dcep dcen either polarity. I welded a metal rack once with nothing but a lincoln a c 225 buzz box and some 5 32 6011 welding rods.

The ultimate guide to welding rod sizes and classifications including the 7018 6013 6011 and 6010 welding rods. Something else that comes to mind is 5 32 6011 rods. The e6013 welding rod is a multi purpose rod suitable for welding of mild steel galvanized steel and some low alloy steels. In general the 7018 rod is used with currents up to 225 amps.

E6011 rods come in 5 32 diameter also and even if all you have is a 200 amp buzz box and e6011 rods you can weld a lot of stuff. A lincoln 225 amp buzz box is perfectly capable of burning 5 32 rods. The correct welding amperage used with this rod depends on the rod diameter. May 31 2020 by mechanicwiz team the e60 11 stick electrode or welding rod is one of the well known fast freeze electrode types.

Although its coating generates a very stable forceful spray like arc this electrode is not as deep penetrating as the e6011 which can penetrate thick or unclean material. The welding rod sustains the welding arc and also provides the filler metal needed for the joint to be permanently bonded together. The forney 31210 e6011 1 8 in. The tensile strength of a welding rod can be determined by the first two numbers in the electrode s name.

In this case that is 60 so the maximum tensile strength of the 6011 and 6013 electrode is 60 000 psi. Proof of purchase required. Whether you are a novice welder or a seasoned pro this chart is a handy tool to keep close while welding.